Biogas from Waste and Renewable Resources ─ An Introduction

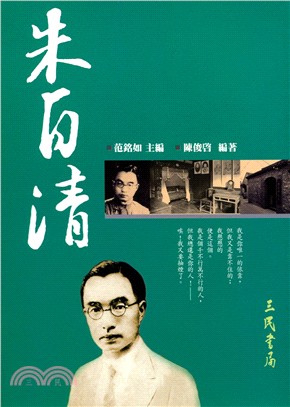

商品資訊

商品簡介

The full range of biogas substrates and processing modes is explained, from agricultural and industrial waste to marine algae and sediment. On-site use of biogas for conversion into electricity, fuel and heat is also discussed, as are safety and regulatory issues. Dozens of real-life examples of European biogas plants already in operation illustrate the contents, as do numerous schemes, diagrams and summary tables.

For the new edition, the authors have included recent advances in the processing of biomass that allows a greater range of substrates to be used, biogas analytics and quality control required for feeding biogas into natural gas networks, and a completely new chapter on the microbiology of biogas-producing bacterial communities.

作者簡介

Angelika Steinhauser studied biotechnology at the Munich University of Technology - Weihenstephan - and has been leading projects in research and development in a large multinational company for the past years. Previously located in Singapore and driven by her strong interest in the potential of biogas production, she has been gathering information on existing plants and current practices in emerging and developed markets in Asia to understand future opportunities. She has captured her knowledge and investigations in this book. She is now based in Europe, Switzerland, and is building on her experience acquired abroad.

目次

Preface to the Second Edition.

Symbols and Abbreviations.

Acknowledgments.

Part One Potential and History.

General Thoughts about Energy Supply.

1 Energy Supply – Today and in the Future.

1.1 Primary Energy Sources.

1.2 Secondary Energy Sources.

1.3 End-Point Energy Sources.

1.4 Effective Energy.

2 Energy Supply in the Future – Scenarios.

3 Potential for Transforming Biomass into End-Point Energy Sources.

3.1 Amount of Available Area.

3.2 Theoretical Potential.

3.3 Technical Potential.

3.4 Economic Potential.

3.5 Realizable Potential.

4 History and Status to Date in Europe.

4.1 First Attempts at Using Biogas.

4.2 Second Attempts at Using Biogas.

4.3 Third Attempts at Applying Biogas.

4.4 Status to Date and Perspective in Europe.

5 History and Status to Date Worldwide.

5.1 History and Status to Date in China.

5.2 History and Status to Date in India.

5.3 Status to Date in America.

5.4 Status to Date in the CIS States.

6 General Aspects of the Recovery of Biomass in the Future.

Part Two Substrates and Biogas.

Introduction.

7 Substrate.

7.1 Agricultural Products.

7.2 Biowaste from Collections of Residual Waste and Domestic Waste Like Commercial Waste.

7.3 Landfi ll for Residual Waste.

7.4 Sewage Sludge and Co-substrate.

7.5 Industrial Waste Water.

7.6 Waste Grease or Fat.

7.7 Cultivation of Algae.

7.8 Plankton.

7.9 Sediments in the Sea.

7.10 Wood, Straw.

8 Biogas.

8.1 Biogas Compared with Other Methane-Containing Gases.

8.2 Detailed Overview of Biogas Components.

Part Three Formation of Biogas.

9 Biochemistry.

10 Bioreactions.

10.1 Hydrolysis.

10.2 Acidogenic Phase.

10.3 Acetogenic Phase.

10.4 Methanogenic Phase.

11 Process Parameters.

11.1 Parameter: Hydrogen Partial Pressure.

11.2 Parameter: Concentration of the Microorganisms (Ensilage, Recirculation of Biomass).

11.3 Parameter: Type of Substrate.

11.4 Parameter: Specifi c Surface Area of Material.

11.5 Parameter: Disintegration.

11.6 Parameter: Cultivation, Mixing, and Volume Load.

11.7 Parameter: Light.

11.8 Parameter: Temperature.

11.9 Parameter: pH.

11.10 Parameter: Redox Potential.

11.11 Parameter: Nutrients (C : N : P Ratio).

11.12 Parameter: Precipitants (Calcium Carbonate, Magnesium Ammonium Phosphate, Apatite).

11.13 Parameter: Biogas Removal.

11.14 Parameter: Inhibitors.

11.15 Parameter: Degree of Decomposition.

11.16 Parameter: Foaming and Scum Formation.

Part Four Microorganisms in Methanogenic Ecosystems.

12 Methanogenic Ecosystems.

12.1 Ecosystems in the Gastrointestinal Tract of Ruminants.

12.2 Ecosystems in the Gastrointestinal System of Herbivores.

12.3 Ecosystems in the Intestine of Termites of Termites.

12.4 Ecosystem in the Soil of a Paddy Field.

12.5 Ecosystems in a Biogas Reactor.

13 Microorganisms in Methanation.

13.1 Protists.

13.2 Fungi.

13.3 Bacteriophages.

13.4 Bacteria and Archaea.

Part Five Dangers with Biogas Plants and Laboratory Equipment.

14 Guidelines and Regulations.

14.1 Regulations Relating to the Construction of Plants.

14.2 Biomass and Residue.

14.3 Feeding Biogas to the Gas Network.

14.4 Risk of Explosion.

14.5 Risk of Fire.

14.6 Harmful Exhaust Gases.

14.7 Noise Protection.

14.8 Prevention of Injuries.

14.9 Protection from Water.

15 The Biogas Laboratory.

15.1 Laboratory Digesters with Eudiometers.

15.2 Pilot Fermenter.

15.3 Larger Pilot Plants for Batchwise or Continuous Fermentation Tests.

15.4 Analyses.

Part Six Equipment of a Biogas Plant.

16 Tanks and Bioreactors.

16.1 Brick Tanks.

16.2 Reinforced Concrete Tanks.

16.3 Tanks of Normal Steel Sheet Metals with an Enamel Layer or Plastic Coating.

16.4 Tanks of Stainless Steel.

16.5 Ground Basin with Plastic Foil Lining.

17 Equipment for Tempering the Substrate.

18 Thermal Insulation.

19 Agitators.

19.1 Mechanical Agitation.

19.2 Circulation Pumps.

19.3 Gas Injection into the Digestion Tower.

19.4 Stirring Effect by Gas Formation.

20 Mixing of Biomass and Water.

21 Machines to Separate the Liquid from the Biomass.

21.1 Belt-type Press.

21.2 Filter Press.

21.3 Decanters.

22 Pipes.

22.1 Substrate Pipework.

22.2 Gas Pipes.

23 Pumps.

23.1 Submerged Centrifugal Pump, Submerged Motor Centrifugal Pump.

23.2 Eccentric Screw Pump, Eccentric Rotor Pump.

24 Measurement, Control, and Automation Technology.

24.1 Mechanisms for Monitoring and Regulation.

24.2 Equipment to Guarantee Operating Safety.

25 Exhaust Air Cleaning.

Part Seven Upstream and Downstream Processing.

26 Transportation and Storage of the Biomass.

26.1 Transport and Means of Transport.

26.2 Storage Silos.

27 Process Technology for Upstream Processing.

27.1 Adjustment of the Water Content.

27.2 Removal of Impurities/Harmful Substances (Figure 27.3).

27.3 Comminution.

27.4 Hygienization.

27.5 Disintegration.

28 Feeding.

28.1 Feeding with Substrate.

28.2 Feeding with Additives.

29 Digested Residue.

29.1 Pressing of the Fermentation Residue.

29.2 Drying.

30 Wastewater.

Part Eight Fermentation – Agricultural Plant.

31 Batchwise and Continuous Processes Without Separators.

31.1 Floating Cup Reactor.

31.2 Fixed-Dome Reactor .

31.3 Deenbandhu Model.

31.4 Plastic Bag Reactor and Plastic Silo Reactor.

31.5 Cavern Plants.

31.6 One-Stage Agricultural Biogas Plants.

32 Existing Installations from Different Suppliers.

32.1 WABIO-Vaasa Process.

32.2 DUT Process.

32.3 Entec Process.

32.4 Bigadan™ Process (Formerly Krüger Process).

32.5 Valorga™ Process.

33 Operation of a Plant Without Separation Equipment.

33.1 Start-up.

33.2 Start-up of the Plant.

33.3 Operation of the Plant.

34 Benefi ts of a Biogas Plant.

35 Typical Design Calculation for an Agricultural Biogas Plant.

36 Economics Calculations for Biogas Plants.

36.1 Capital-Bound Costs Per Year in US$.

36.2 Consumption-Bound Costs Per Year.

36.3 Operation-Bound Costs Per Year.

36.4 Other Costs Per Year.

36.5 Total Costs.

36.6 Income Per Year.

36.7 Annual Revenue of the Biogas Plant.

37 Efficiency.

Part Nine Fermentation – Industrial Plants.

Fermentation.

38 Installation with Substrate Dilution and Subsequent Water Separation.

38.1 Process Engineering.

38.2 Implemented Installations of Different Manufacturers.

39 Installation with Biomass Accumulation.

39.1 Sewage Sludge Digestion Tower Installation.

39.2 Sludge-Bed Reactor.

39.3 Reactors with Immobilized Microorganisms.

40 Plants with Separation of Non-Hydrolyzable Biomass.

40.1 Process Engineering and Equipment Construction.

40.2 Efficiency.

40.3 Plant Installations.

41 Percolation Process.

41.1 Dry Fermentation Process in a Stack.

41.2 AN/Biothane™ Process.

41.3 Prethane™/Rudad™–Biopaq™ Process or ANM Process.

41.4 Foil Hose Process.

41.5 IMK Process.

41.6 Dry Anaerobic Composting.

41.7 Aerobic–Anaerobic–Aerobic Process (3A Process).

41.8 Fermentation Channel Process.

42 Special Plant Installations.

42.1 Combined Fermentation of Sewage Sludge and Biowaste.

42.2 Biowaste Plants.

42.3 Purification of Industrial Wastewater.

Part Ten Biogas Storage and Preparation.

43 Biogasholder.

43.1 Biogasholder Types.

43.2 Gas Flares.

44 Gas Preparation.

44.1 Removal of Hydrogen Sulfide.

44.2 Removal of the Carbon Dioxide.

44.3 Removal of Oxygen.

44.4 Removal of Water.

44.5 Removal of Ammonia.

44.6 Removal of Siloxanes.

45 Quantities of Gas and Measurement of Gas Quality.

46 Liquefaction or Compression of the Biogas.

46.1 Liquefaction.

46.2 Compression.

Part Eleven Biogas Utilization.

Utilization of Biogas to Generate Electric Power and Heat.

47 Utilization of Gas Exclusively to Generate Heat.

48 Utilization of Gas to Generate Current and Heat.

48.1 Supply of Current to the Public Power Network.

48.2 Heat.

48.3 Combined Heat and Power Generator (CHP).

48.4 Lessons Learnt from Experience.

48.5 Economy.

49 Biogas for Feeding into the Natural Gas Network.

49.1 Biogas for Feeding into the Natural Gas Network in Switzerland.

49.2 Biogas for Feeding into the Natural Gas Network in Sweden.

49.3 Biogas for Feeding into the Natural Gas Network in Germany.

50 Biogas as Fuel for Vehicles.

50.1 Requirements on Gas When Used as Fuel.

50.2 Vehicles.

50.3 Gasoline Station.

Literature.

Index.

主題書展

更多書展本週66折

您曾經瀏覽過的商品

購物須知

外文書商品之書封,為出版社提供之樣本。實際出貨商品,以出版社所提供之現有版本為主。部份書籍,因出版社供應狀況特殊,匯率將依實際狀況做調整。

無庫存之商品,在您完成訂單程序之後,將以空運的方式為你下單調貨。為了縮短等待的時間,建議您將外文書與其他商品分開下單,以獲得最快的取貨速度,平均調貨時間為1~2個月。

為了保護您的權益,「三民網路書店」提供會員七日商品鑑賞期(收到商品為起始日)。

若要辦理退貨,請在商品鑑賞期內寄回,且商品必須是全新狀態與完整包裝(商品、附件、發票、隨貨贈品等)否則恕不接受退貨。